Diamond, CBN, and SYNTHETIC DIAMOND wheels, have only a thin layer of very hard abrasive, highly concentrated over the grinding surface. Because of this high concentration of abrasive, plated wheels will cut very freely, are less likely to load than conventional wheels, and be produced to almost any profile.

Wheels cannot be trued on the spindle and therefore, electroplated wheel mounting allows you to ensure the wheel is clocked accurately before commencing grinding. Failure to do so will usually cause premature breakdown or serious damage to the wheel and could result in damage to your equipment and machinery. It is not possible to dress an electro plated wheel but, loaded wheels can be cleaned by scrubbing vigorously with detergent.

In general electro plated wheels are designed to operate in the speed range 4,500 – 6,000 s.f.p.m. although for small routers, internal grinders, cone points etc, the operating speed is usually lower, dependent upon the equipment available and the safety regulations governing these small mounted points.

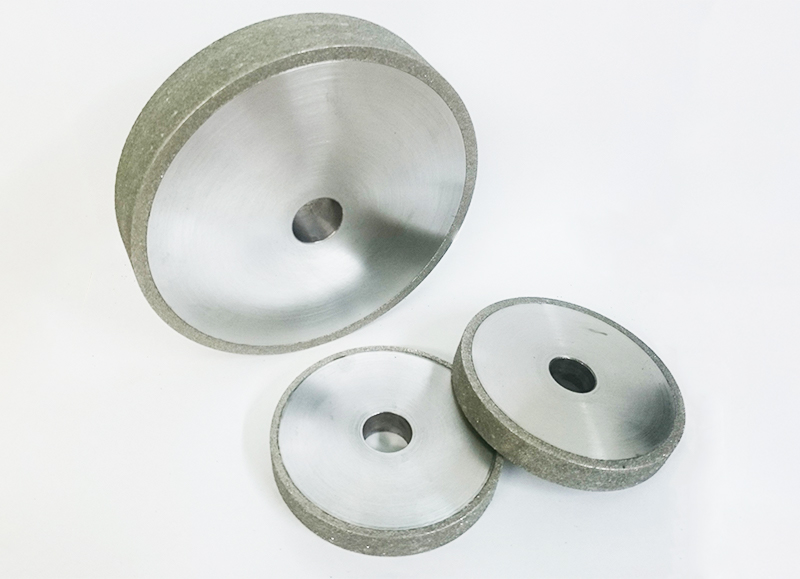

Can be plated up to 450mm diameter. We can manufacture from your drawings or samples.

Require one of our services?

Simply click the button to get in touch and let us know your requirments